Description

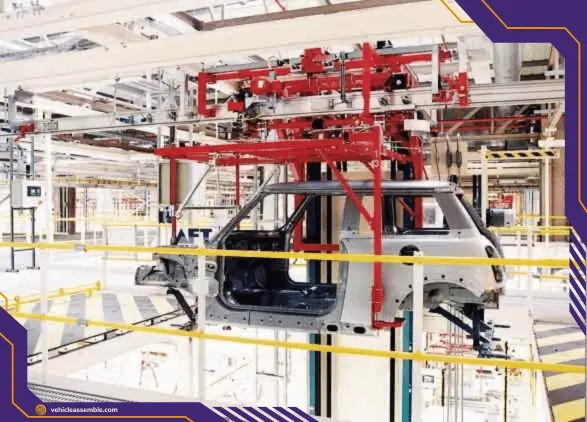

Assembly Line Suspended Power Truss: Enhancing Efficiency in Car Assembly Lines

This comprehensive article explores the assembly line suspended power truss, its role in car assembly lines, and its impact on efficiency. Learn how this innovative system streamlines production and boosts productivity.

Introduction

In the fast-paced world of automotive manufacturing, efficiency and productivity are paramount. Car assembly lines require seamless processes to meet the growing demand for vehicles. The Assembly Line Suspended Power Truss is a cutting-edge solution that optimizes assembly line operations, enhancing productivity and reducing downtime. This article will explore the Assembly Line Suspended Power Truss, its features, benefits, and impact on the car assembly process.

The Assembly Line Suspended Power Truss: Understanding the Basics

The Assembly Line Suspended Power Truss is a sophisticated system that delivers power, data, and utilities to various stations along the car assembly line. It consists of a network of suspended trusses that run parallel to the assembly line, providing a flexible and efficient means of delivering essential resources. These trusses have various outlets and connectors that allow seamless integration with assembly line machinery.

Advantages of the Assembly Line Suspended Power Truss

Implementing the Assembly Line Suspended Power Truss offers numerous advantages to car manufacturers. Let's take a closer look at some of the key benefits:

Streamlined Power Distribution

The Assembly Line Suspended Power Truss eliminates the need for extensive wiring and cabling on the assembly floor. With power outlets conveniently located along the truss, each station can easily access electricity, minimizing the risk of tripping hazards and reducing clutter.

Enhanced Flexibility and Scalability

Car assembly lines often require reconfiguration to accommodate different vehicle models. The suspended power truss offers unparalleled flexibility, allowing manufacturers to adapt the production layout quickly. This system also supports scalability, making it easy to add new workstations as production demands increase.

Improved Safety and Ergonomics

The Assembly Line Suspended Power Truss significantly improves workplace safety by keeping power and utility cables elevated and organized. It minimizes the risk of workers coming into contact with exposed wires and contributes to a more ergonomic and efficient work environment.

Increased Productivity

With streamlined power distribution and reduced reconfiguration downtime, the assembly line can operate at its full potential, leading to increased productivity and faster production cycles.

Cost Savings

While the initial investment in the Assembly Line Suspended Power Truss may seem substantial, the long-term cost savings are undeniable. Reduced downtime, enhanced productivity, and improved safety measures ultimately lead to a more cost-effective production process.

Implementing the Assembly Line Suspended Power Truss

Integrating the Assembly Line Suspended Power Truss into an existing car assembly line involves meticulous planning and execution. Let's explore the steps involved in the successful implementation of this innovative system:

Initial Assessment and Planning

Before installation, a comprehensive assessment of the assembly line's layout and power requirements is necessary. Manufacturers need to determine the optimal placement of the suspended trusses and calculate the power needs of each workstation.

Customization and Fabrication

Each assembly line is unique, and the power truss system must be customized accordingly. Manufacturers work closely with the truss supplier to design and fabricate a strategy that meets their specific production requirements.

Equipment Description

The load-bearing structure is designed in such a way as to avoid stress concentration. It takes the steel roof beam of the workshop as the supporting point, with a hanging point below, and stretches down by connecting to an upright post. Facilities on the power truss attach the position lights, power supply cables (AC380V. AC220V), compressed air pipelines, industrial fans, etc.

Equipment Description

The driving shaft, #45 steel, adopts an integral solid shaft to ensure an equal phase angle of the two gears. After heat treatment and quenching treatment, to provide comprehensive mechanical properties and tooth surface hardness. An overload protection pin is used between the transmission and traction chains to prevent the motor reducer from overloading effectively. There is no crawling phenomenon on the assembly line at the lowest speed.

Remark

Demander can designate functional configurations and bought-in components.

Installation and Testing

The installation of the Assembly Line Suspended Power Truss requires precision and expertise. Qualified technicians handle the installation process, ensuring the trusses are securely suspended and all connections are correctly established. Rigorous testing is conducted to verify the functionality and safety of the system.

Training and Familiarization

Once installed, assembly line workers undergo training to understand the system's operation and safety protocols. Familiarization with the new setup ensures smooth integration into daily production activities.

FAQs

What sets the Assembly Line Suspended Power Truss apart from traditional power distribution systems?

The Assembly Line Suspended Power Truss offers unmatched flexibility, scalability, and safety advantages compared to traditional cable-based power distribution systems.

Is the installation of the power truss system time-consuming?

While the installation requires precision, it is faster than traditional wiring methods. The benefits of improved productivity and safety outweigh the installation time.

Can the power truss accommodate additional utility connections beyond electricity?

Yes, the power truss can be equipped to deliver compressed air, data connections, and other utilities required in car assembly processes.

What happens if a power truss component malfunctions?

The power truss system is designed for reliability, but manufacturers have access to technical support and maintenance services in the rare event of a malfunction.

Does the power truss system work with robotic assembly equipment?

The suspended power truss can seamlessly integrate with robotic systems, providing them with the necessary power and data connections.

Is the Assembly Line Suspended Power Truss cost-effective for small-scale manufacturers?

Increased productivity and safety benefits are valuable for manufacturers of all sizes. Small-scale manufacturers can also experience a positive return on investment with this system.

Conclusion

The Assembly Line Suspended Power Truss revolutionizes car assembly lines by streamlining power distribution, enhancing flexibility, and boosting overall productivity. With its numerous advantages, including improved safety and cost savings, this innovative system is a game-changer for the automotive manufacturing industry. By embracing the power truss, manufacturers can take their production capabilities to new heights, meeting the demands of a dynamic market while ensuring a safe and efficient working environment.