Description

Car Welding Line: A Comprehensive Guide to Automotive Assembly

This informative article delves into the world of car welding lines, exploring their importance in automotive assembly. Learn about the processes, equipment, and advancements revolutionizing car manufacturing.

Introduction

The Car Welding Line is an integral part of modern automotive assembly, where various components come together to form a cohesive unit. This process involves joining metal parts through welding techniques, ensuring the structural integrity and safety of the automobile. In this in-depth guide, we will explore the intricacies of car welding lines, the advanced technologies used, and their significance in the automotive industry.

Car Welding Line: Understanding the Basics

The Car Welding Line encompasses various stages, from the assembly of individual components to the final welding and inspection processes. Let's delve into each step to gain a comprehensive understanding:

Welding Line Preparation

Before the welding process begins, meticulous planning and preparation are crucial. Engineers carefully design the welding line layout, ensuring efficiency and minimizing material wastage. Advanced simulation software aids in optimizing the welding sequence, which helps achieve maximum productivity.

Component Assembly

The first step in the car welding line involves assembling various components, such as the chassis, doors, roof, and engine parts. Robots or skilled workers precisely handle this phase to guarantee accurate positioning, alignment, and fit.

Body-in-White (BIW) Stage

The Body-in-White (BIW) stage assembles the car's skeletal structure. The car's frame comprises the floor, side panels, roof, and pillars. Laser-based measurement systems ensure that the BIW components adhere to strict dimensional specifications.

Welding Techniques Used

In the car welding line, several welding techniques are employed, including:

Resistance Spot Welding: This method utilizes electrodes to apply pressure and heat to the metal sheets, creating a solid bond at specific points.

MIG Welding (Metal Inert Gas): MIG welding uses a consumable wire electrode to join metal pieces, producing high-quality welds with excellent structural integrity.

TIG Welding (Tungsten Inert Gas): TIG welding is commonly used for precise welding, especially stainless steel and aluminum components.

Robotic Welding in Automotive Assembly

Robotic welding has revolutionized car manufacturing, significantly improving efficiency and accuracy. Advanced robotic arms with welding torches perform intricate tasks with unmatched speed and precision.

Quality Inspection and Testing

After the welding process, each vehicle undergoes a rigorous quality inspection and testing. Modern technologies, such as 3D scanning and X-ray inspections, are employed to detect any defects or imperfections in the welds.

Advancements in Car Welding Line Technologies

With rapid technological advancements, the automotive industry has substantially improved car welding lines. Some notable innovations include:

Adaptive Welding Systems

Adaptive welding systems use sensors and cameras to monitor the welding process in real time. The data collected helps adjust the welding parameters, ensuring consistent quality even when dealing with material variations.

Laser Welding Applications

Laser welding has gained prominence due to its ability to deliver precise, high-quality welds with minimal heat-affected zones. This technology is ideal for welding lightweight materials like aluminum, improving fuel efficiency and overall vehicle performance.

Virtual Reality (VR) Training for Welders

Virtual Reality (VR) training allows welders to simulate welding tasks in a virtual environment, enhancing their skills without compromising safety. This technology is invaluable for training new welders and upskilling existing ones.

Collaborative Robots (Cobots) in Welding

Collaborative robots, or cobots, work alongside human welders, aiding them in repetitive tasks and ensuring better ergonomics. These robots enhance productivity and safety on the car welding line.

Car Welding Line: Ensuring Safety and Structural Integrity

Car welding lines are vital in ensuring our vehicles' safety and structural integrity. The welding process creates a robust bond between metal components, providing the necessary strength to withstand various stresses encountered during the car's lifespan.

Crashworthiness and Safety Standards

The welding quality directly affects the crashworthiness of the vehicle, as well as compliance with safety standards. Car manufacturers adhere to strict regulations to guarantee that their vehicles can withstand collisions and protect passengers effectively.

Corrosion Resistance

Proper welding techniques and materials contribute to the corrosion resistance of the car's body. This ensures the vehicle's longevity and preserves its appearance and value over time.

Structural Rigidity

Practical welding ensures the car's structural rigidity, reducing vibrations and enhancing the driving experience. This is crucial for stability and handling, especially in challenging road conditions.

The Future of Car Welding Lines

As technology continues to evolve, so will the car welding line. Innovations on the horizon include:

Artificial Intelligence (AI) Integration

AI integration in car welding lines will enable autonomous adjustments to welding parameters, improving efficiency and consistency.

Lightweight Materials Integration

With the rise of electric vehicles, car manufacturers are exploring lightweight materials like carbon fiber in automotive assembly. Welding processes will need to adapt to handle these materials efficiently.

Eco-Friendly Welding Techniques

Future welding techniques will likely focus on reducing environmental impact by minimizing energy consumption and emissions.

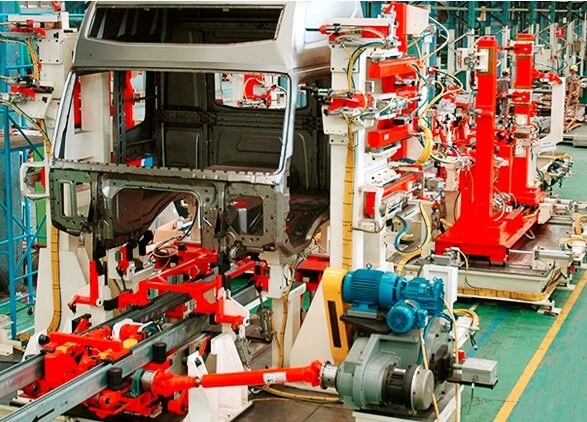

Car Production Line Process

Identical to other vehicle production lines, Duoyuan can also provide CKD/SKD production lines with the service of Design, processing, transportation, installation, commissioning, paternity, and training. The car production line consists of a car welding line, car painting line, car assembly line, and car testing line. If it's the SKD process, it's only the car assembly and testing lines.

Customers of Duoyuan equipment on CAR PRODUCTION LINE/CAR ASSEMBLY LINE

Focus on the automobile industry for more than 20 years, DUOYUAN provides the best service to our customers, just like HAIMA vehicle, GEELY auto, FAW auto, and NISSAN.

Welding Jigs for Nissan Auto:

FAQs

What is the significance of a car welding line in the automotive industry?

The car welding line is critical in the automotive industry by ensuring vehicles' structural integrity, safety, and longevity. It allows for precise assembly and welding of components, contributing to the car's overall quality.

How has robotic welding transformed automotive assembly?

Robotic welding has revolutionized automotive assembly by increasing productivity, ensuring consistent weld quality, and enhancing worker safety. Robots can perform complex welding tasks with unmatched accuracy and speed.

What materials are commonly used in car welding lines?

Steel and aluminum are the most commonly used materials in car welding lines due to their strength, durability, and cost-effectiveness. However, with the advent of electric vehicles, manufacturers are exploring lightweight materials like carbon fiber.

Are there any environmental concerns associated with car welding lines?

While welding processes can consume significant energy, advancements in eco-friendly welding techniques aim to minimize environmental impact and reduce emissions.

How do car manufacturers ensure welding quality?

Car manufacturers employ advanced technologies like 3D scanning and X-ray inspections to ensure the quality of welds and detect any defects or imperfections.

What role will AI play in the future of car welding lines?

AI integration will likely lead to autonomous adjustments in welding parameters, improving efficiency and consistency during welding.

Conclusion

The Car Welding Line is a fundamental aspect of modern automotive assembly, with technologies continually evolving to ensure safety, structural integrity, and efficiency. From robotic welding to advanced AI integration, the future of car welding lines is promising, catering to the growing demands of the automotive industry. As new technologies emerge, car manufacturers will continue to innovate, shaping the future of transportation with enhanced safety and environmental considerations.