Description

Comprehensive Guide to Welding Jigs in Car Manufacturing

Uncover welding jigs' role, types, and advantages in the car manufacturing industry. This comprehensive guide details the significance of welding jigs and their applications in creating world-class automobiles.

Introduction

Welding jigs, an integral component in the car manufacturing industry, significantly influence vehicle production's efficiency, safety, and quality. These fixtures ensure consistent, high-quality welds, reduce manufacturing times, and lower production costs. This article delves deep into the intricate world of welding jigs, the linchpin of the auto-manufacturing arena.

Understanding Welding Jigs in Car Manufacturing

Welding jigs are custom-designed tools to hold the welded parts in a specific alignment. They enable precision and consistency, contributing to superior weld quality in car manufacturing.

Types of Welding Jigs

Numerous welding jig variants serve specific purposes in the car manufacturing line. These include:

Handheld Jigs: These are manual fixtures handled by welders to align and stabilize parts during welding. They offer flexibility but require skilled handling.

Table Jigs: These large, robust fixtures offer superior hold, ensuring the best precision and consistency for more significant parts or assemblies.

Robotic Jigs: These automated fixtures and robotic welders offer maximum efficiency and precision in high-volume production scenarios.

Key Components of a Welding Jig

Understanding the constituent parts of a welding jig aids in maximizing its benefits. The primary components include the base plate, clamping devices, and locators.

Importance of Welding Jigs in Car Manufacturing

Car manufacturing demands precision, consistency, and speed. Welding jigs play a pivotal role in satisfying these demands.

Enhancing Quality

With exact alignment and secure parts holding, welding jigs ensure high-quality, consistent welds across the production line.

Boosting Efficiency

Welding jigs streamline the welding process by reducing the time spent aligning and securing parts, thereby increasing the overall efficiency of the car manufacturing line.

Reducing Costs

By reducing labor requirements and rectification time for misaligned welds, welding jigs contribute significantly to cost savings in car manufacturing.

Applications of Welding Jigs in Car Manufacturing

In a car manufacturing line, welding jigs find applications in various stages.

Chassis Assembly

During the car's chassis assembly, welding jigs ensure the accurate alignment and welding of various structural elements.

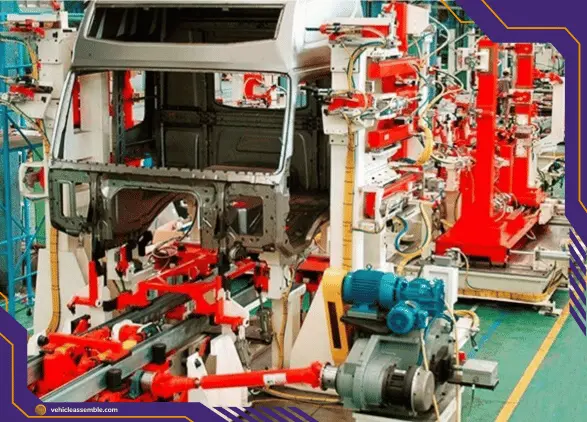

Body Shell Assembly

Welding jigs hold body panels and other components in place during the car's body shell assembly, facilitating precise welding and maintaining the desired body shape.

Accessory Mounting

Welding accessory mounts onto the vehicle frame is another crucial application of welding jigs in car manufacturing.

Choosing the Right Welding Jig for Your Car Manufacturing Line

Selecting the right welding jig depends on various factors like production volume, the complexity of the part, and available workforce skills.

Assessing the Requirements

A thorough analysis of the welding requirements can guide the selection of the most appropriate jig.

Evaluating the Options

Assess the pros and cons of different types of welding jigs to find the one that best fits your manufacturing line.

Services provided by DUOYUAN

Our welding tables are completely customizable using our unique welding jigs, fixtures, tools, and accessories to create the perfect solution for all your welding needs. Our tools allow you to move and change your welding table to easily accommodate all sizes and shapes of welding projects for the best welding experience.

Every welding jig is designed according to your product specifications and welding requirements. We ensure that the design allows high accessibility for both the welding robot and the operator and is user-friendly and cost-effective.

The welding jigs are separate from the robotic welding positioners. They are attached to the face of the welding positioners enabling synchronized movements with the welding robot and allowing the workpiece to be moved and rotated to provide the robotic welding system with the utmost accessibility.

Depending on the client's preferences, Welding jigs can have either pneumatic or manual clamps. Clamps are positioned on the welding jig for accessibility and ease of use while keeping the workpiece securely attached for welding.

To learn more about our equipment sets, tools, and accessories and how they are used, call Duoyuan today.

Advancements in Welding Jig Technology

The technological evolution has also touched welding jigs, enabling even more efficient and precise operations in car manufacturing.

Automated Welding Jigs

Robotic welding jigs offer unmatched precision and efficiency, particularly for high-volume production.

Smart Welding Jigs

Bright jigs incorporate advanced sensors and control systems, providing real-time feedback and adjustments during welding.

FAQs

What are welding jigs in car manufacturing?

Welding jigs are tools for holding and aligning parts welded in car manufacturing. They enable precise and consistent welds, contributing to superior quality production.

Why are welding jigs essential in car manufacturing?

Welding jigs enhance the quality of welds, boost efficiency by reducing alignment and securing time, and lower production costs by minimizing labor and rectification needs.

What are some applications of welding jigs in car manufacturing?

Welding jigs find application in various stages of car manufacturing, including chassis assembly, body shell assembly, and accessory mounting.

How do I choose the right welding jig for my car manufacturing line?

Choosing the right welding jig involves assessing your welding requirements and evaluating the pros and cons of different jig types to find the most suitable one.

What advancements have been made in welding jig technology?

Technological advancements in welding jigs include the development of automated and intelligent jigs that offer enhanced precision, efficiency, and real-time feedback.

What are the components of a welding jig?

The primary components of a welding jig include the base plate, clamping devices, and locators.

Conclusion

Welding jigs, the unsung heroes in the car manufacturing process, are pivotal to the efficiency and quality of production. Understanding their types, applications, and advantages enables optimization of the welding process and elevates the standard of car manufacturing.