Double-Station Top Skin Automatic Spot-Welding Machine

Discover the transformative impact of the Double-Station Top Skin Automatic Spot-Welding Machine in the car assembly line. This article takes you through the fundamentals of its operation, its importance, and how it's changing the automobile industry.

Description

Revolutionizing Car Assembly: Double-Station Top Skin Automatic Spot-Welding Machine

Discover the transformative impact of the Double-Station Top Skin Automatic Spot-Welding Machine in the car assembly line. This article takes you through the fundamentals of its operation, its importance, and how it's changing the automobile industry.

Double-Station Top Skin Automatic Spot-Welding Machine: An Introduction

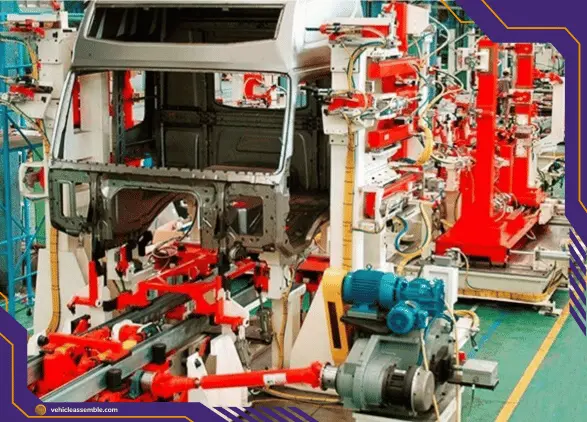

The world of car manufacturing has always been a place of innovation and evolution. And at the heart of this landscape lies a game-changer - the Double-Station Top Skin Automatic Spot-Welding Machine. A technological marvel, it's the driving force behind improving production efficiency and quality in the car assembly line.

The Double-Station Top Skin Automatic Spot-Welding Machine is a specialized tool designed to optimize joining two overlapping metal sheets or components - a vital task in car manufacturing. It applies heat and pressure at specific points, creating a durable joint without damaging the surrounding area or distorting the components.

Components and Working Principles

Understanding the components and working principle of the Double-Station Top Skin Automatic Spot-Welding Machine can give us a clear insight into its efficiency.

Machine Components

The primary components of the machine include:

Welding Transformer: A device that lowers the input voltage to a suitable level for welding.

Welding Electrodes: Conductive pieces that deliver the electric current to the welding zone.

Control Unit: Directs the machine’s operations, including timing and welding sequence.

Pneumatic System: Controls the movement and pressure applied by the electrodes.

Cooling System: Ensures the machine remains within operational temperatures during welding.

Equipment Description :

The production efficiency is greatly enhanced by the automatic transport between the two stations through the transmission cart. The equipment consists of multiple systems: two supporting positioning systems, a stretching machine, a gantry welding system, a transmission cart, an NC system, etc.; it can be applied to the top frame with parameters of length between 6 to 12m, width 1.8 to 2. 5m, and height 150 to 400mm.

Operation Process :

The top frame is sat on the positioning system. One end of the entire skin is welded on the edge, and the other is clamped on the tension system to stretch the skin. Then spot welding machine is used for positioning welding.

Equipment Structure :

Automatic Spot Welding System :

The equipment adopts two sets of AC servo motors and a reducer. The gantry is driven by a gear and rack device to step on the guide rail to ensure synchronization and accurate positioning. Walking speed is less than 15m/min.

Equipped with two sets of welding systems, double-sided spot welding is adopted, and both sides of the roof skin and frame are completed simultaneously. Self-contained circulating cooling system, reliable cooling effect.

Open programming, parameter preset with memory function. The welded joint's position (height and width) can be adjusted. The roof frame positioning device can be adjusted according to the different types of vehicles, which is convenient and fast.

Main Technical Parameters

|

External Size |

Depends on the type of the bus |

|

Power Voltage |

380V±15% |

|

Power Frequency |

50Hz±2% |

|

Total Power of Equipment |

7.5KW |

|

Hydraulic System Pressure |

16Mpa |

|

Stretching Oil Cylinder |

φ80*200, 7 sets |

|

Applicable Body Width |

1.8~2.55m |

Working Principle

The machine follows a specific principle when executing its operations:

Electrodes Clamp: The two electrodes clamp the pieces of metal to be welded together.

Heat Generation: A high current is passed through the clamped pieces, which generates heat due to the resistance encountered.

Creation of Weld Nugget: The heat causes the interfaces of the metals to melt, forming a 'weld nugget.'

Cooling and Solidification: The weld nugget cools and solidifies to form a robust joint, completing the spot welding process.

Role in Car Assembly Line

The car assembly line is a fast-paced environment where efficiency is critical. Let's see how the Double-Station Top Skin Automatic Spot-Welding Machine makes a difference.

Improved Quality

Thanks to its precision and control, the machine significantly enhances the quality of welds. It delivers consistent, high-quality results that can withstand the stresses and strains vehicles face on the road.

Comparison with Traditional Welding Methods

The Double-Station Top Skin Automatic Spot-Welding Machine is not the only welding method used in car assembly. However, it has advantages that set it apart.

Speed and Efficiency

Although effective, traditional welding methods, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), are slower and require more manual labor. Our machine is significantly faster and more efficient with its double-station setup and automatic controls.

Quality and Consistency

Manual welding methods can lead to inconsistent results due to human error. In contrast, the Double-Station Top Skin Automatic Spot-Welding Machine ensures consistent, high-quality welds every time.

Maintenance and Safety Measures

Like all machinery, our spot-welding machine also requires regular maintenance and adherence to safety measures to ensure optimum performance and longevity.

Maintenance: Regular maintenance includes cleaning the electrodes, inspecting the welding transformer, and checking the pneumatic system. It is also vital to routinely monitor the machine’s control unit for any potential issues.

Safety Measures: include wearing appropriate protective gear, ensuring proper ventilation, and regularly checking the machine’s components for wear and tear.

Market Prospects and Future Trends

As the automobile industry grows, the demand for efficient, high-quality welding solutions like the Double-Station Top Skin Automatic Spot-Welding Machine also increases.

Market Prospects

As more automotive manufacturers recognize the machine’s benefits, the market for this technology is expected to grow. It is a significant investment for companies looking to enhance productivity and product quality.

Future Trends

Looking forward, the industry's future trends include increased automation and integration of intelligent technology. As technology advances, we can expect welding machines that are even more efficient, accurate, and easy to operate.

FAQs

What is a Double-Station Top Skin Automatic Spot-Welding Machine?

It is a highly efficient tool used in car manufacturing that spot-welds two overlapping metal sheets or components at two points simultaneously.

How Does a Double-Station Top Skin Automatic Spot-Welding Machine Work?

It uses two electrodes to apply pressure and heat to the metal pieces, creating a durable weld. This process is carried out at two separate stations for increased productivity.

Why is a Double-Station Top Skin Automatic Spot-Welding Machine essential in a car assembly line?

It is crucial due to its capacity to enhance productivity and improve weld quality, both vital factors in car manufacturing.

How does a Double-Station Top Skin Automatic Spot-Welding Machine differ from traditional welding methods?

This machine is faster and more efficient than conventional welding methods, offering consistent, high-quality welds due to its automation.

What maintenance does a Double-Station Top Skin Automatic Spot-Welding Machine require?

Regular maintenance includes cleaning the electrodes, inspecting the welding transformer, checking the control unit, and monitoring the pneumatic system.

What safety measures should be followed when operating a Double-Station Top Skin Automatic Spot-Welding Machine?

Safety measures include wearing protective gear, ensuring proper ventilation, and regularly checking the machine's components for wear and tear.

Conclusion

The Double-Station Top Skin Automatic Spot-Welding Machine is revolutionizing the car assembly line. With its enhanced productivity, improved weld quality, and excellent efficiency, it is a game-changing technology for the automobile industry. As we continue to advance in automation and intelligent technology, the future seems promising for this exceptional machine.